The 3D printing revolution and its future impact

The 3D printing revolution is well underway, and it is radically transforming a range of industries. This innovative technology is changing how products are designed, manufactured, and distributed. From the medical field to the automotive industry, 3D printing, also known as additive manufacturing, is opening up new possibilities and promising a future of limitless potential.

The Evolution of 3D Printing

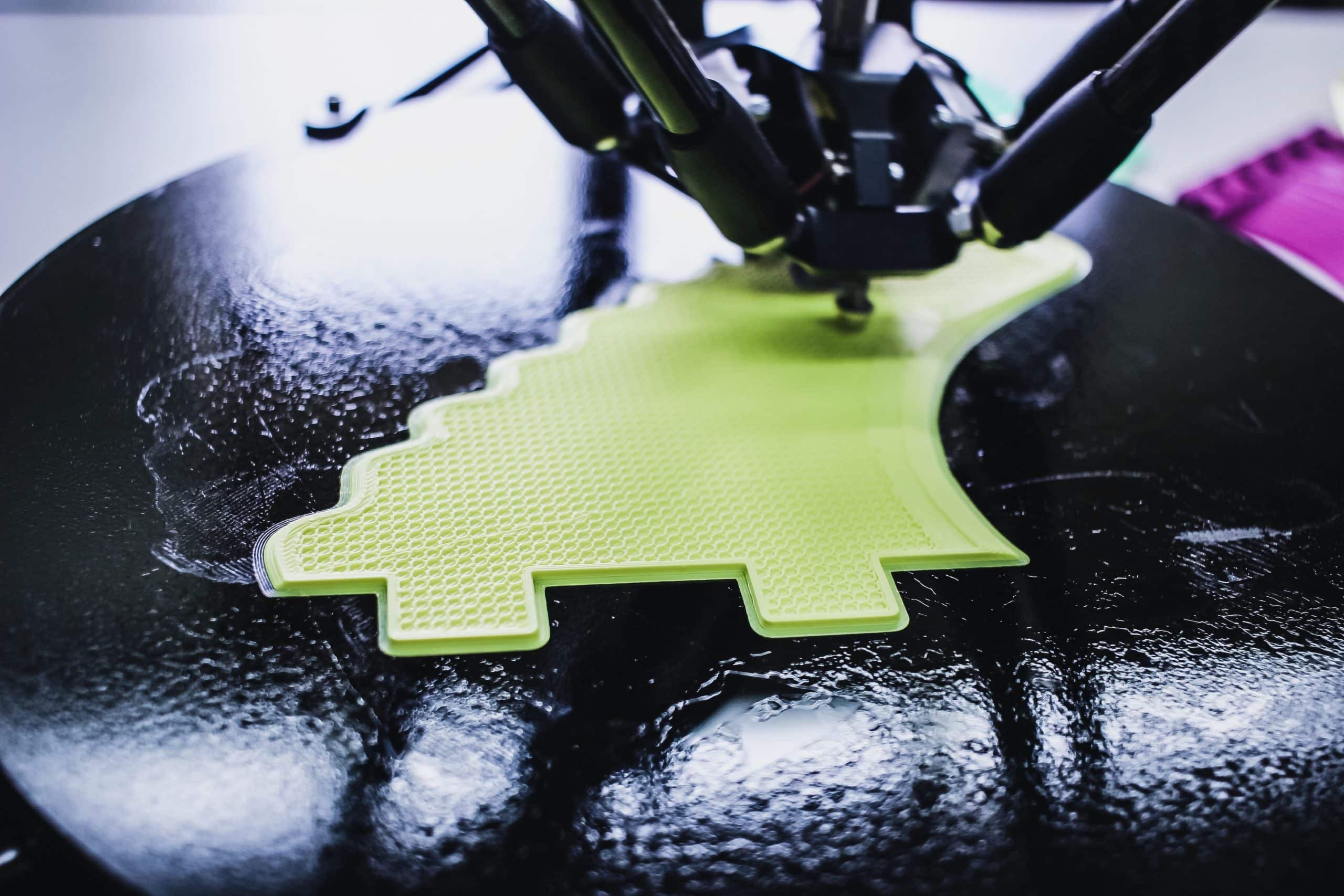

The advent of 3D printing marked a significant shift in production capabilities. The process involves creating solid, three-dimensional objects from digital files, enabling manufacturers to produce complex shapes using less material than traditional manufacturing methods.

En parallèle : Cybersecurity: new emerging threats

The technology has existed for over 30 years, but only in the last decade has it become accessible to a broader market. Advancements in 3D printing technology, coupled with decreasing costs, have pushed it from a niche product to a mainstream manufacturing option.

3D printers can now be found in factories and homes alike, creating everything from automotive parts to prosthetic limbs. This level of accessibility has revolutionized the manufacturing industry, offering a viable alternative to mass production, particularly for customized and low-volume products.

En parallèle : Unlock hidden treasures with the pokemon go mystery box

In the next section, we’ll delve deeper into how 3D printing is impacting different industries.

3D Printing: A New Frontier in Manufacturing

In recent years, the application of 3D printing has expanded beyond prototyping to include the production of final products. From automotive parts to medical devices, the potential applications are expanding rapidly.

In the automotive industry, for instance, 3D printing has drastically reduced the time and cost of producing parts. Companies can now print complex parts on-demand, reducing supply chain complexities and enabling faster time-to-market. Major car manufacturers have already adopted this technology, with BMW, for instance, recently announcing that it has printed over one million parts in just a few years.

In the medical field, the application of this technology is nothing short of revolutionary. Surgeons can now print patient-specific anatomical models for pre-surgical planning. Dental professionals are creating custom dental prosthetics, while researchers are advancing towards printing human tissues and organs.

The Future of 3D Printing

With the current pace of technological advancements, the future of 3D printing looks promising. As more industries recognize the potential of this technology, its adoption will continue to grow.

The development of new materials for 3D printing is one area of significant potential. While plastics and metals are currently the most commonly used materials, ongoing research is expanding the range of printable materials to include ceramics, composites, and even biomaterials. This expansion will open up new possibilities for product design and broaden the usage of 3D printing across different industries.

Moreover, advancements in printer speeds and resolution are making it feasible to produce larger, more intricate products in less time. This will further accelerate the adoption of 3D printing in mass manufacturing.

Overcoming Challenges for Widespread Adoption

While the potential of 3D printing is undeniable, challenges persist that hinder its widespread adoption. These include technical limitations, high upfront costs, and regulatory concerns.

The technical limitations of 3D printing mainly revolve around issues like speed, accuracy, and material capabilities. While improvements are being made, these challenges can limit the types of products that can be effectively 3D printed.

High upfront costs can also be a barrier to entry for smaller companies. Although 3D printing can reduce costs in the long term, the initial investment in printers and materials can be substantial.

Regulatory concerns, particularly in industries like healthcare, also pose a significant hurdle. As 3D printed products become more complex, it’s crucial for regulatory bodies to keep up with the technology to ensure patient safety and product efficacy.

Conclusion

While there are hurdles to overcome, the impact of 3D printing on the manufacturing industry is already profound and will continue to grow in the coming years. By enabling on-demand production, reducing waste, and opening up new possibilities for product design, 3D printing is set to revolutionize the manufacturing landscape.

Through continuous research and development, and with increasing adoption, 3D printing stands as a testament to human innovation. It is an exciting time as we witness the unfolding of this technology’s potential and await the countless innovations it will surely bring.

3D Printing and the Transformation of Supply Chains

The impact of 3D printing, or additive manufacturing, is not limited to production processes alone. As the technology matures, we are witnessing a profound effect on supply chains across different sectors. By enabling localized production and reducing the need for complex logistics, 3D printing is transforming the way businesses operate and strategize.

Traditional supply chains typically involve mass manufacturing in low-cost regions, followed by shipping products to various markets. This model often results in high inventory costs and complex logistics, and it is vulnerable to disruptions in transportation. On the other hand, additive manufacturing enables a shift towards a demand-driven model, which can significantly reduce lead times, inventory costs, and carbon footprint.

For instance, in the spare parts industry, long-tail items with low demand and high storage costs are prime candidates for 3D printing. Companies can produce these parts on-demand, closer to the customer, thus eliminating the need for large inventories and reducing delivery times. Leading logistics providers, such as UPS and DHL, have already started integrating 3D printing into their services, highlighting the transformative potential of this technology on supply chains.

Beyond logistics, 3D printing also promises greater flexibility and customization. As consumer demand is increasingly leaning towards personalized products, the ability to seamlessly customize and adapt product designs is a significant advantage. With additive manufacturing, businesses can easily modify digital designs and print products tailored to individual customer requirements, opening up new market possibilities.

The Growth of the 3D Printing Market

The future of the 3D printing industry looks promising, with growth anticipated across a variety of sectors. As the technology continues to mature and become more accessible, its market presence will expand. According to a report by SmarTech Analysis, the additive manufacturing market is expected to reach $35.6 billion by 2024, showcasing the industry’s robust growth potential.

This growth is expected to be driven by several key sectors, including healthcare, aerospace, and automotive. For example, in the healthcare industry, 3D printing will continue to revolutionize the manufacturing process of medical devices, prosthetics, and even organ transplants. Similarly, in the aerospace and automotive sectors, 3D printing will enable the production of lighter and more fuel-efficient components, thereby contributing to sustainable manufacturing goals.

Moreover, the open-source nature of many 3D printing technologies encourages innovation and accelerates the adoption of the technology. This collaborative approach combines shared knowledge with individual creativity, leading to rapid prototyping and continuous improvement in design and functionality.

As the demand for personalized goods continues to rise, businesses will need to adapt their manufacturing processes to stay competitive. In such a scenario, 3D printing emerges as an effective solution, offering customization at scale without significant cost increments.

Conclusion

The 3D printing revolution is undeniably poised to transform traditional manufacturing and supply chain landscapes. While challenges persist, ongoing advancements in technology and materials are gradually overcoming these hurdles.

The benefits that additive manufacturing brings to the table – from streamlined supply chains to personalized production – are too significant to overlook. It is clear that the influence of 3D printing will continue to grow, reshaping industries and innovating processes along the way.

In the future, 3D printing will be not just an alternative but an integral part of the manufacturing industry. By reducing waste, lowering costs, and enabling mass customization, the technology stands as a testament to human innovation. As we continue to witness the unfolding of its potential, we look forward to the countless transformations it will bring to our world.